Company Profile

Glotech Industrial Corp.

Established in 1997, Glotech Industrial Corp. is headquartered at No. 718, Section 2, Yanghu Road, Yangmei District, Taoyuan City, Taiwan. The company operates two subsidiaries: Glotech Electronics (Suzhou) Corp. and Deyu Composite Material Co., Ltd

Through steady and integrity-driven development, the company has grown into a high-tech enterprise with registered capital of RMB 287 million, total capital of RMB 644 million, and over 200 employees.

As Taiwan's third largest fiberglass fabric manufacturer, we specialize in R&D, production, and sales of electronic-grade fiberglass fabrics. Our professional technical team continuously innovates to deliver cutting-edge product quality and services, adhering to the sustainable business philosophy of "rooted in Taiwan with a global vision".

With production bases in Suzhou, China and Taiwan, our products have gained international recognition across Europe, North America, China, Japan, and South Korea.

Recognizing industry integration trends, we acquired upstream fiberglass yarn manufacturer Dexing Technology Materials Corp. in 2007 to achieve raw material autonomy and product diversification. The 2010 expansion of weaving machines significantly increased annual fiberglass fabric production capacity, realizing complete vertical integration.

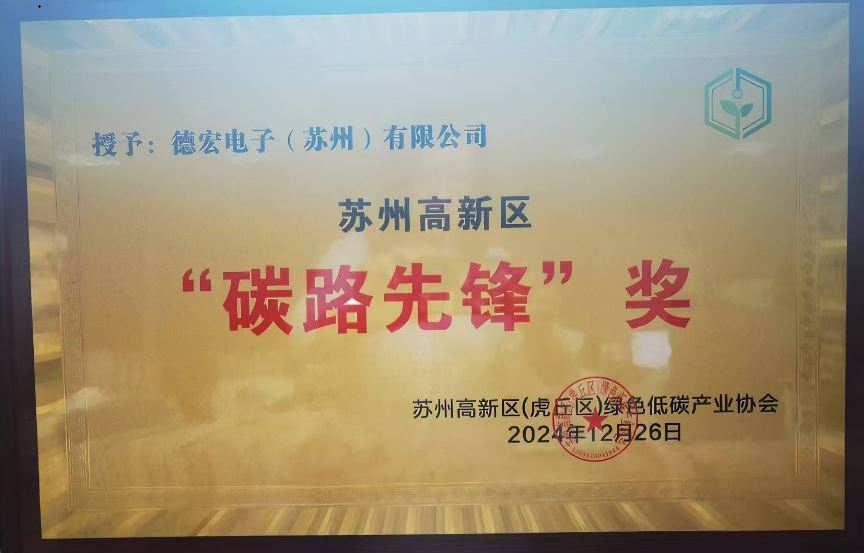

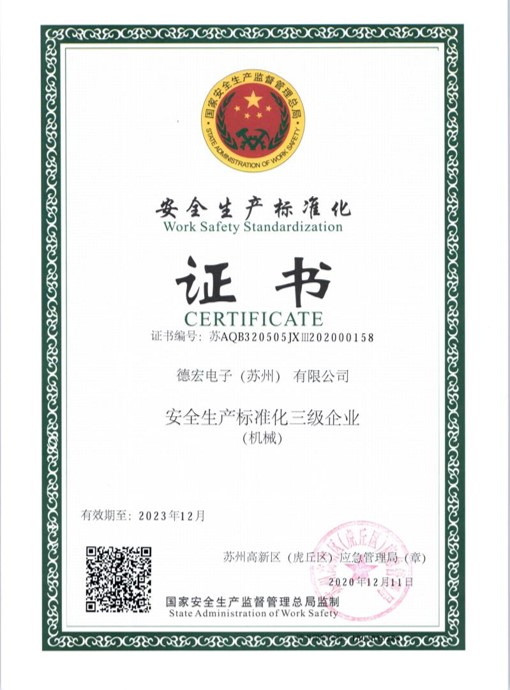

Glotech Electronics (Suzhou) Corp.

Established in 2000 and located at No. 136 Huashan Road, Suzhou New District, Jiangsu Province, Glotech Electronics (Suzhou) Corp. is a wholly foreign-owned high-tech enterprise invested by Taiwan-listed Glotech Industrial Corp., covering an area of 50 mu (approx. 8.2 acres).

With total investment of approximately US$55.7 million and factory buildings spanning 30,000㎡, the company commenced production in March 2004. It obtained ISO 9000 and ISO 14001 certifications in 2005, achieved Work Safety Standardization Enterprise Certification in 2014, and was recognized as "Jiangsu Provincial High-Tech Enterprise" in 2006.

Since its establishment, the company has built a strong reputation in both domestic and international fiberglass fabric markets through its professional team, advanced technologies, and steady development. The company focuses on production automation and process technology R&D, while also committing to environmental protection. Its products are well received by customers.

The company's primary products include fiberglass fabric, quartz fiber yarn, and quartz fiber fabric. Among these, the fiberglass fabric is produced using glass fiber as the raw material and is treated with a silane coupling agent on the fabric surface. It is primarily supplied to downstream copper clad laminate (CCL) manufacturers, with a current monthly production of 8 million meters of electronic-grade fiberglass fabric.

As a high-tech enterprise integrating textile, chemical, and electronic technologies, Glotech Electronics (Suzhou) continues to drive innovation while delivering premium products and services.

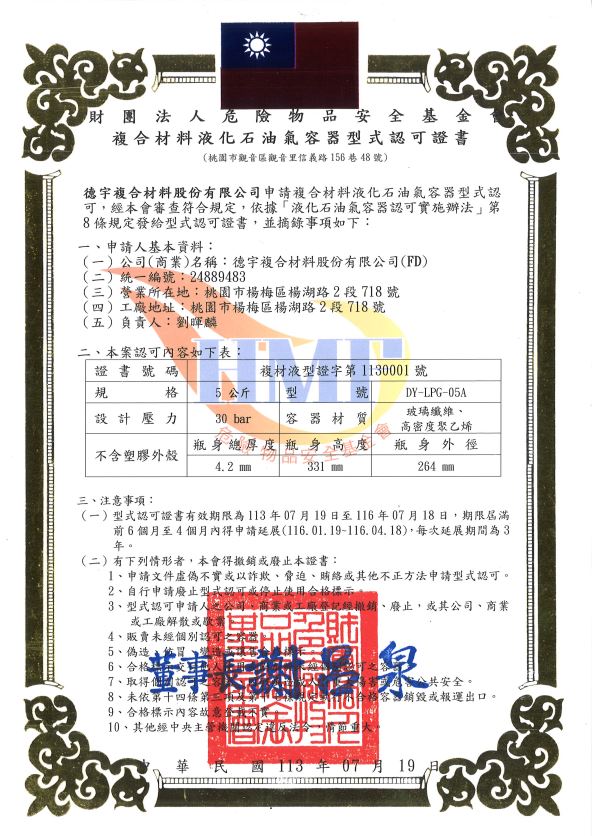

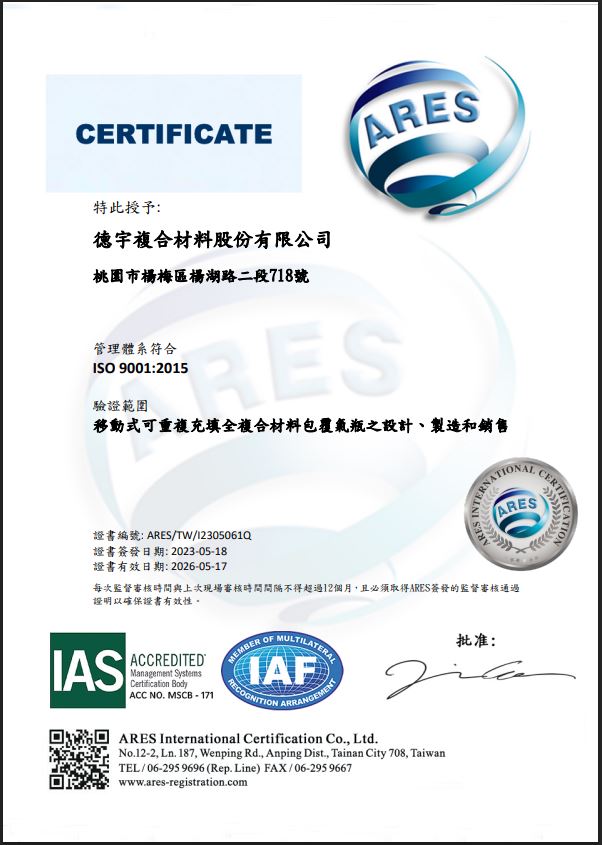

Deyu Composite Material Co., Ltd

Established in 2015 and headquartered at No. 718, Section 2, Yanghu Road, Yangmei District, Taoyuan City, Taiwan, Deyu Composite Material Co., Ltd is a subsidiary invested by Taiwan-listed Glotech Industrial Corp.

In 2015, through collaboration with Taiwan's National Chung-Shan Institute of Science and Technology (NCSIST) on composite material LPG container commercialization, we established Deyu Composite Material Co., Ltd in partnership with LPG industry leaders, specializing in production and sales of composite LPG containers while continuously developing advanced composite pressure vessels.

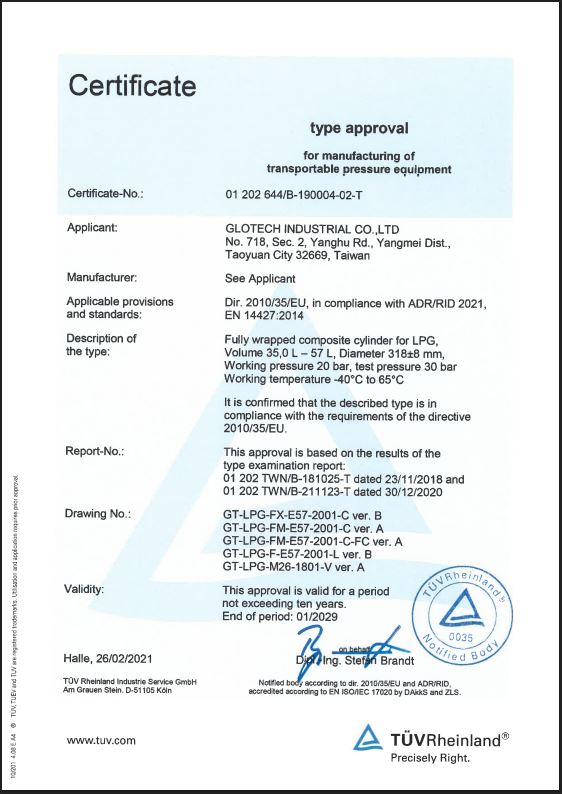

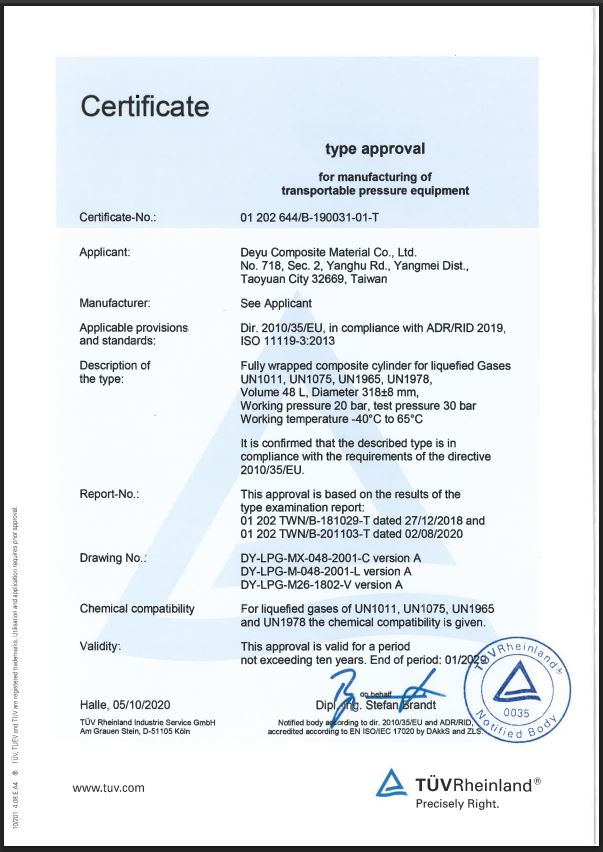

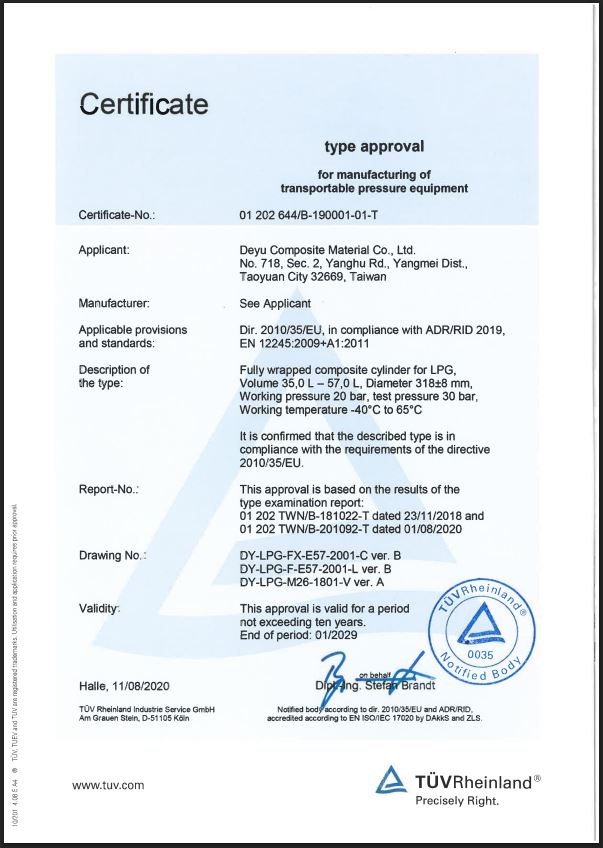

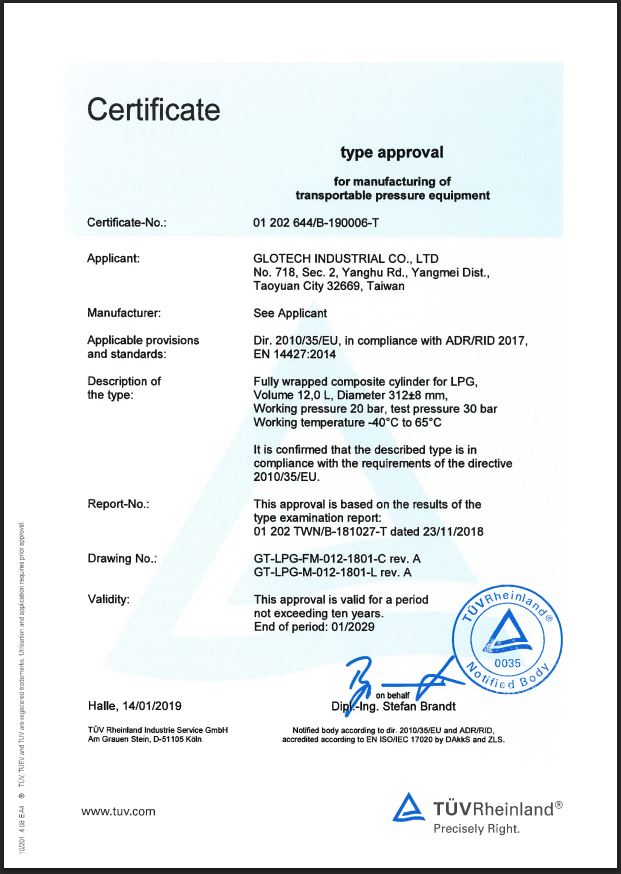

As Taiwan's exclusive designer and manufacturer of composite LPG containers, Deyu's products have obtained multiple domestic and international certifications, offering superior quality at competitive prices. Our products are exported to Philippines, Mongolia, UAE, and other countries. Recently, we developed 5kg compact cylinders and camping stove systems using LPG (propane) fuel delivering 5.8KW high heat output. Our composite gas containers feature lightweight construction and high safety, ideal for outdoor applications.

We provide complete Type IV (non-metallic) composite cylinder solutions for LPG, CNG, and industrial compressed gases, creating safer, more durable, and convenient pressure vessels.

With proprietary production equipment and real-time manufacturing capabilities, Deyu holds TPED/ADR certifications and TÜV Rheinland certificates. Our full self-manufacturing capabilities and efficient quality management set industry benchmarks.

Aligning with global net-zero carbon emission initiatives, Deyu is developing Type IV high-pressure hydrogen storage cylinders, collaborating with domestic and international partners to advance carbon neutrality goals.